Well well well....would you Adam&Eve it....the "180 monster" strikes again !

OK, I have the car on ramps to replace the Accumulator sphere, all going well with Suspension depreurising and the car dropping down per book.

Here I am working on the suspension then the 180-Monster attacks ! Every time I work on a Car he strikes :)...work on one thing and you will see a fault that is totally 180 degrees from what you are working on and completely unconnected.

So this time its ???????................as I work on the Suspension....I get a WATER Leak ! geeeze

A split seam in the Degass Tank...RATS !

OK, So I have it seems a leaking "DeGass Tank" also known as a Swirl Pot. This device is a pressure pot with an internal flow that allows micro bubbles (generated in a hot high performance engine when working hard) to be trapped in the water and collect in areas of the engine.

This greatly reduces cooling in certain "HotSpots" and is not unknown to cause head failures and binding pistons or valves....NOT Good.

PSA group in their wisdom make this part in a plastic that over the years goes brittle with heat and pressure changes. So where do they put this ?, yep ...close to the exhaust LOL...gj

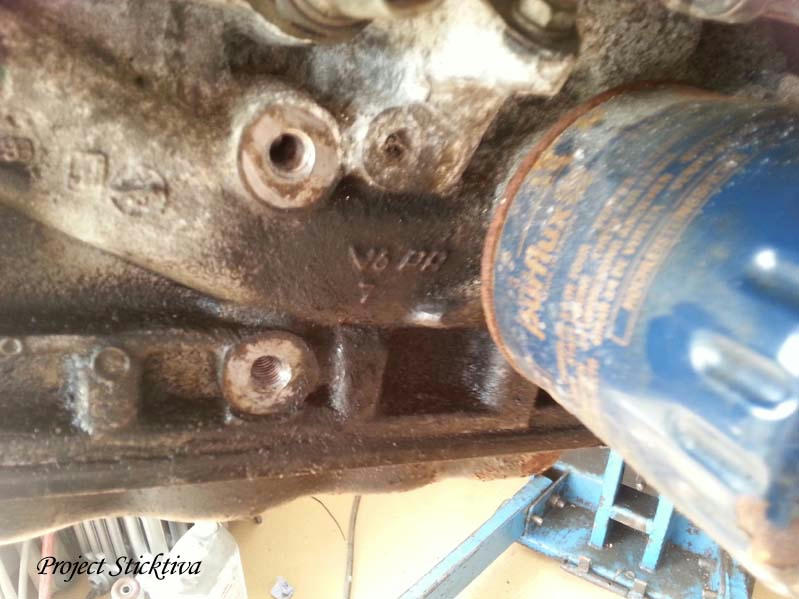

This is how it is positioned (shown on the spare engine out of the car :) )

Deep down in the bowels of the engine as well as at the rear....nice access... uggg NOT

The strip down starts in stages with cleaning as I go.

Here we see the header tank (taken from the spares car next to the one removed from this car. Note this is a prime example as to how these parts fail, note the staining at the leaking seam.

This spreading is DIRECTLY caused by the type of (1980's) plastic used combined with limescale contaminating the type of seal used in production.

NEVER USE TAP WATER in this ENGINE...it WILL KILL IT....

Use ONLY Distilled Water

My advice is to drain and refill with distilled water/AFz mix for 1 month, change that each month for every two years of the cars age.

I discovered a few other problems on the way, here I found a split induction tube.

The Green Goblin one is a good spare so I will refit it with that one.

.....nice to have a spares car !

So I took off the Induction/air filter pipe work and box. I removed the Header Tank taking care with the sender unit and pipes which must be remove before being able to extract the tank.

I now have better access to the Degass Tank, that's better, yes I have long arms and will have to lay over the engine....scratches here we come.

More tomorrow.